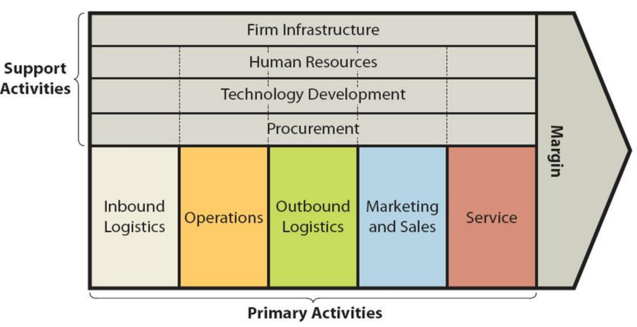

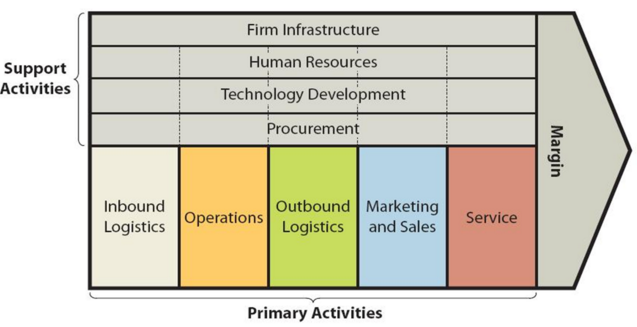

Value-Chain Analysis

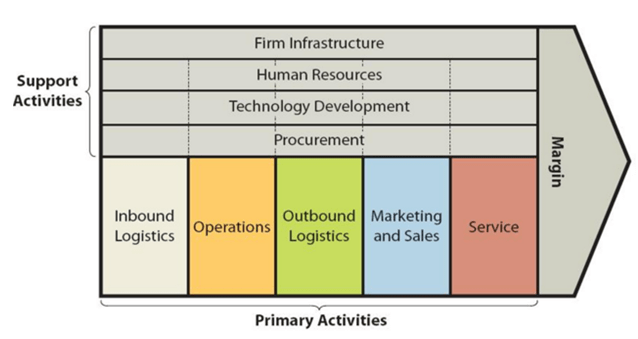

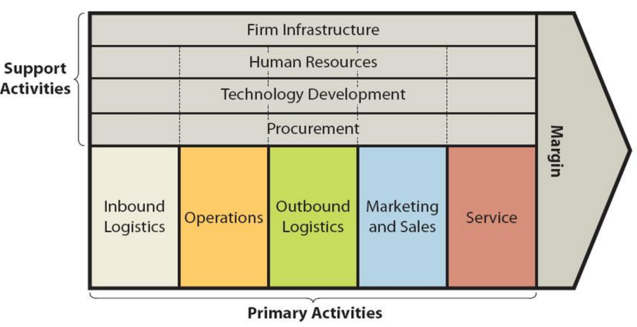

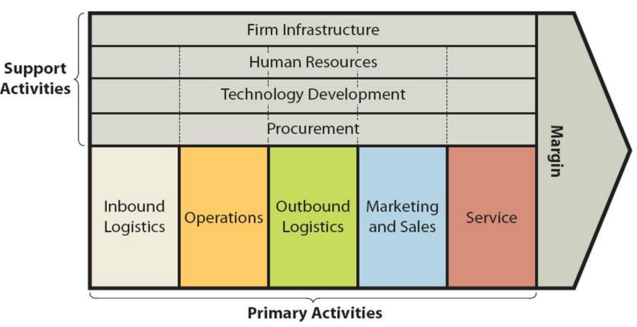

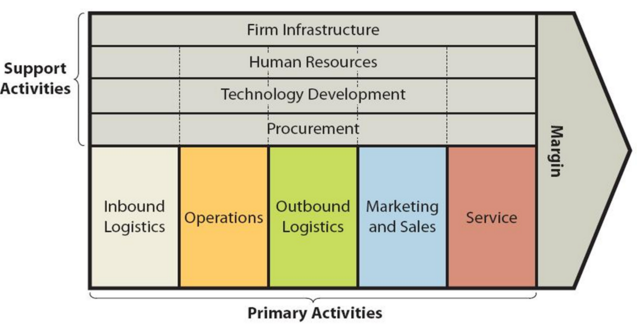

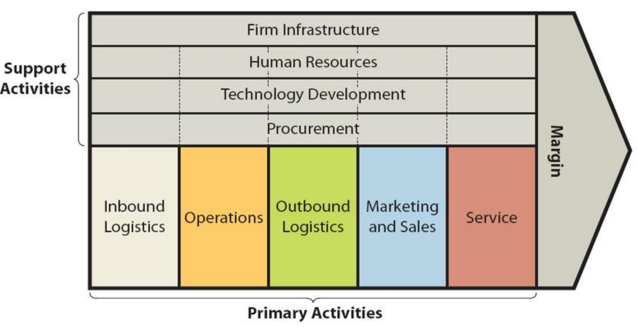

Value chain analysis is a strategic analytical tool that analyses the sources of value creation for businesses. Gap Inc. value chain analysis presented below critically analyses the most important primary and support activities that contribute to the competitive advantage of the apparel and accessories retailer. The figure below illustrates the essence of value chain analysis. Gap Inc. Value chain analysis Primary Activities Inbound logistics Gap Inc. inbound logistics involves purchasing from about 1,000 vendors that have factories in about 40 countries. During the fiscal year of 2015, approximately 99 percent of purchases, by dollar value, were from factories outside the United States, while the remaining 1 percent of all purchases were from domestic factories. Moreover, about 24 per cent of total purchases by dollar value during the same period were made from factories based in China.[1] Due to the massive purchase volumes, economies of scale can be specified as the main sources of value creation for Gap Inc. Moreover, the company benefits from strategic, long-term relationships with its suppliers. In 2016, the company embraced supplier transparency practices disclosing the list of factories that produce its clothes around the world.[2] Operations GAP Inc. business operations are conducted in two formats[3]: Gap Inc. has company-operated stores in the United States, Canada, the United Kingdom, France, Ireland, Japan, Italy, China, Hong Kong, Taiwan, and beginning in October 2015, Mexico. The company also has franchise agreements with unaffiliated franchisees to operate Gap, Banana Republic, and Old Navy stores throughout Asia, Australia, Europe, Latin America, the Middle East, and Africa. Gap Inc. has 3,721 company-operated and franchise store locations throughout the world. The company derives value in operations primary activities mainly through opening its stores in locations and shopping centers frequently attended by the representatives of the target customer segment. Outbound logistics Gap Inc.…

Value chain analysis is a strategic analytical tool that that is used to identify business activities important to create value and competitive advantage to the business. The figure below illustrates the essence of eBay value chain analysis. eBay Value chain analysis Primary Activities Inbound logistics eBay inbound logistics refers to ways in which the company acquires and stores raw material to be used for the business. This includes but not limited to the purchase of servers, other hardware products and a wide range of technological items along with office suppliers and other items. Due to the massive scope and scale of eBay business operations, the economies of scale can be specified as the major source of value in inbound logistics primary activities. Moreover, fostering strategic relationships with suppliers is another key source of value in eBay’s inbound logistics. Operations eBay operations revolve around technology-enabled commerce. The full range of eBay technologies and services are divided into the following three platforms: Marketplace refers to an online marketplace available at www.ebay.com. This platform has more than 800 million listings at any given time[1] StubHub represents a platform to purchase tickets to the games, concerts and theatre shows and to sell tickets. Classifieds platforms include a collection of brands such as Mobile.de, Kijiji, Gumtree, Marktplaats, eBay Classifieds and others. Ebay classifieds are offered in more than 1500 cities globally. The full range of eBay business operations include the following processes: Seller registering on eBay website Buyers bidding for a specific product offered by the seller A successful bid by a specific Buyer (or purchasing via ‘Buy It Now’) Buyer paying to the bank via PayPal or other payment methods Bank notifying eBay about Buyer’s purchase eBay notifying Seller about the payment by Buyer The delivery (shipment) of the product by the Seller…

Hilton value chain analysis identifies business activities that can create value and competitive advantage to the business. The framework of value chain analysis divides business activities into two categories: primary and support activities. The figure below illustrates the essence of value chain analysis: Hilton Value Chain Analysis Primary Activities Inbound logistics Hilton inbound logistics represents a highly sophisticated system that ensures smooth operations in 572 hotels and resorts in 85 countries around the world.[1] Hilton’s “procurement group aggregates buying into national contracts for its various brands, and enables local providers where it makes sense to do so”[2] Hilton’s supply chain management and inbound logistics is unique in a way that the company makes deals directly with suppliers, then negotiates markups with the distributors that handle warehousing and delivery. This practice is an important source of value for the business since it enables the control of the whole supply chain. Operations Hilton Worldwide operates its business via the following three segments: Ownership segment. This segment consists of 146 hotels with 59,463 rooms which are owned or leased by Hilton Worldwide. Management and franchise segment consists of 4,419 hotels with 691,887 rooms. These are owned by third parties and managed by Hilton Worldwide. The company also licences its brand to franchises. As of December 2015, Hilton Worldwide franchised 3,875 hotels with 533,039 rooms. Timeshare segment consists of 45 properties comprising 7,152 units. This segment is engaged in marketing and selling timeshare intervals, operating timeshare resorts and timeshare membership clubs and providing consumer financing. Hilton operations are divided into four geographical segments: Americas Europe Middle East and Africa Asia Pacific The main sources of value in Hilton’s business operations include the highest level of standard of service, a high level of service personalization and integration of information and communication technologies into the various…

Red Bull value chain analysis is an analytical tool that can be applied to identify business activities that can create value and competitive advantage for the company. Figure below illustrates the essence of value chain analysis: Primary Activities Inbound logistics Operations With more than 5.9 billion cans sold in 2015 alone[1], the scope of Red Bull operations is extensive. The Red Bull flavouring is still produced in Bangkok and exported into manufacturing plants internationally. Wall-to-wall manufacturing technique is one of the main sources of value for Red Bull in operations primary activity. Wall-to-wall manufacturing technique involves manufacturing and filling cans on the same site and saving 8,750,000 km of truck travel annually, with highly positive implications from financial and environmental points of view.[2] Outbound logistics Red bull is sold in more than 169 countries[3] and its outbound logistics represents a complex system reflecting the size of the business. Red Bull Energy Drinks travel to their destination predominantly by train and ship. The company uses trucks only when it’s absolutely necessary. The use of train and ship is more cost-effective compared to trucks and this one of the important points in Red Bull value chain in outbound logistics. Red Bull cans are 40 per cent more space effective and 30 per cent more space effective compared to glass bottles and PET bottles containing the same quantity respectively[4]. Therefore, shape and light weight of Red Bull cans makes transportation much easier, an additional considerable source of value chain in outbound logistics operations. Marketing and sales. ‘Red Bull gives you wings’ represents an essence of Red Bull marketing communication message. This message is transmitted via a wide range of marketing communication channels on print TV and online platforms. Red Bull Media House five print magazines, one TV channel and an online TV…

British Airways value chain analysis involves the adoption of a systematic approach in the analysis of competitive advantage. The framework makes a distinction between primary and support business activities identifies the sources of competitive advantage for each activity. The figure below illustrates the essence of value chain analysis. Primary Activities Inbound logistics British Airways inbound logistics operations are complex and involve the timely delivery of fleet of planes, catering products and a wide range of other on-board products. The necessity to ensure the freshness of foods and drinks served during the flights further complicates British Airways inbound logistics primary activities. Competitive advantage is achieved in inbound logistics stage of the business by British Airways through establishing on-going relationships with suppliers, sophisticated system for stock control and professional training that has been accredited by UK City and Guilds. Operations Generally, operations stage of the business involves preparing goods and services to be sold to customers. As the UK’s largest international scheduled airline, British Airways flies globally to more than 400 destinations. Therefore, the scope of its business operations is extensive. British Airways has a range of competitive advantages in operations part of the business through offering its customers increased security for their luggage, offering quick check-in services and also offering some services such as ticket bookings and online booking of other services. Moreover, a high level of customization of service provision and an extensive utilization of digital technologies in a wide range of business processes represent solid sources for additional value for British Airways. Outbound logistics Outbound logistics involves sending ready products to customers for consumption. Although outbound logistics mainly relate to manufacturing companies, it is also applicable towards service businesses such as airlines. British Airways flies to airports in nearly 80 countries worldwide. The airline derives value in outbound…

Value chain analysis is an analytical framework that assists in identifying business activities that can create value and competitive advantage to the business. The figure below illustrates the essence of value chain analysis. Tesco value chain analysis Primary Activities Inbound logistics Tesco inbound logistics operations are complex and involve the supply of hundreds of product categories to 7817 Tesco stores around the world[1]. Economies of scale due to the large scope of its operations is a major source of value creation for Tesco. The company makes regular investments to increase the capacity of logistics so that the economies of scales can be exploited to a greater extent. For example, in 2013 as a part of a government-backed trial program testing the efficacy of longer trailers, Tesco received 25 new 51-foot Gray & Adams refrigerated units. New trailers can carry 51 cages (UK shipping units), six more than a standard 45-foot trailer. This change resulted in 13 per cent increase in logistics productivity[2]. The company has a history of poor supplier treatment under the previous leadership that involved the cases of payment delays to improve Tesco’s operational profit margins[3] and unnecessary and unjustified fines being imposed to suppliers[4] with negative implications on various aspects of supply chain practices. However, the new management led by new CEO Dave Lewis announced its commitment to form strategic relationships with suppliers. Operations Tesco operations can be divided into three large segments: 1. Retail. This segment represents the core business of Tesco PLC. With more than 80 million shopping trips made thousands of Tesco shops in 11 countries around the world[5], the scope of Tesco’s retail operations is extensive. The company operates stores in the following format: Metro. Metro stores sell wide range of food and a smaller selection of general items such as cook ware…

Value chain analysis is an analytical tool used to identify the ways in which businesses create value for customers. The essence of value chain analysis is illustrated in Figure 1 below: Figure 1. PepsiCo Value chain analysis Primary Activities Inbound logistics PepsiCo portfolio comprises 22 brands including Pepsi-Cola, Tropicana, Gatorade, Mountain Dew and Diet Pepsi and each brand belonging to PepsiCo generated at least one billion USD in retail sales in 2015.[1] Inbound logistics practices of each brand within PepsiCo portfolio reflect the nature and quantity of raw materials used, the proximity between the location of suppliers and manufacturing plant and other set of factors. The economies of scale can be specified as the main source of value for PepsiCo derived from inbound logistics primary activity. PepsiCo also benefits from locating its production sites within close geographical proximity to the main sources of raw materials in order to save on transportation costs. Technology is another driver of innovation that provides advantage to PepsiCo’s supply chain. One of the innovations that PepsiCo is exploring is 3D printing. For example, RUFFLES® Deep Ridged used 3-D printing technology to create optimal potato chip prototypes.[2] Operations PepsiCo operations are divided into the following the following six operational segments: Frito-Lay North America (FLNA). This segment engages in manufacturing, marketing, distributing and selling branded snack foods. Quaker Foods North America (QFNA). This segment is assigned with producing, marketing, distributing and selling cereals, rice, pasta and other branded products. Latin America segment produces markets, distributes and sells a several snack food brands for Latin American market. These brands include Doritos, Cheetos, Marias Gamesa, Ruffles, Emperador, Saladitas,Sabritas, Lay’s, Rosquinhas Mabel and Tostitos. Asia, Middle East & North America (AMENA). AMENA segment makes, markets, distributes and sells a number of leading snack food brands including Lay’s, Kurkure, Chipsy, Doritos, Cheetos and…

Value chain analysis is an analytical framework that can be used to identify business activities that can create value and competitive advantage to the business. Figure 1 below illustrates the essence of value chain analysis. Figure 1 BMW Value chain analysis Primary Activities Inbound logistics BMW Group has around 13,000 suppliers located internationally[1]. BMW adds value in its inbound logistics primary activity via minimizing transportation costs and sourcing the raw materials of the highest quality. As it is illustrated in Figure 2 below, the company purchases most of its raw materials from Germany (42.6%) and Eastern Europe (19.7%). This is because the majority of manufacturing and assembly units are based in Germany and Europe and the company purchases from trusted suppliers in close proximity in order to reduce the costs of logistics and ensure an undisputed supply. Figure 2 Regional mix of BMW purchase volumes[2] Operations BMW Group is divided into the following four business segments: Automotive. In 2015, this segment generated the gross profit margin of 17.7 per cent. Motorcycles. Gross profit margin in motorcycles segment in 2015 amounted to 22.5 per cent. Financial Services. This segment deals with providing credit financing and leasing for BMW Group brand cars and motorcycles to retail customers. Gross profit margin in financial services segment equalled to 13.3 per cent in 2015. Other Entities. In 2015, this segment generated EUR 211 million profit before tax, which is EUR 57 million higher than the previous year. BMW runs a complex manufacturing network in 30 sites in 14 countries[3]. The company opened its latest engine plant in Shenyang, China in January 2016. In terms of sales BMW Group is represented in more than 150 countries worldwide. BMW Group adds value to its operations primary activity mainly via the use of robotics technologies to a considerable…

Value chain analysis is an analytical framework that assists in identifying business activities that can create value and competitive advantage to the business. The figure below illustrates the essence of value chain analysis. Walmart Value chain analysis Primary Activities Inbound logistics It has been estimated that more than 50 per cent of Walmart products in the US come from overseas suppliers[1] and about 75 percent of walmart.com sales come from non-store inventory [2]. Generally, Walmart inbound logistic practices are based on the following three principles: Using the minimum amount of links in the supply chain. Starting from 1980s, Walmart began to ruthlessly eliminate traders in its supply chain opting to work with manufacturers directly. Such a strategic decision proved to have a positive impact on the bottom line after a few years. Specifically, “in 1989, Wal-Mart was named Retailer of the Decade, with distribution costs estimated at a mere 1.7% of its cost of sales – far superior to competitors like Kmart (3.5%) and Sears (5%)”[3]. The efficiency of Walmart supply chain practices has further improved since in a consistent manner. Forming strategic partnerships with vendors. Walmart imposes strict conditions on various aspects of the business when negotiating with potential suppliers. The company also attempts to purchase for the lowest prices applying its huge bargaining power in order to be able to maintain cost leadership competitive advantage. However, once a potential vendor is contracted as a supplier, Walmart offers a strategic partnership for long-term perspective and engages in high volume purchases, although for lower prices. Using cross docking as an inventory tactic. Cross docking implies “the direct transfer of products from inbound or outbound truck trailers without extra storage, by unloading items from an incoming semi-trailer truck or railroad car and loading these materials directly into outbound trucks, trailers, or…

Value chain analysis is an analytical framework that assists in identifying business activities that can create value and competitive advantage to the business. Figure 1 below illustrates the essence of value chain analysis. You can learn the theory of value chain analysis here. Figure 1 Value chain analysis Primary Activities Inbound logistics Inbound logistics for Toyota comprises two separate operations. The first is the operation “that transports parts from local suppliers to the local plants; the second is a separate operation, global inbound logistics, to transport parts from Japan to the North American and European plant”.[1] Localization of production is one of the core strategies pursued by Toyota and accordingly, 75.4% and 76.3% of non-domestic sales were produced outside of Japan for the calendar years of 2012 and 2013 respectively.[2] Thanks to localization of production, Toyota is able to achieve better match of local currency revenues with local currency expenses. Moreover, Toyota has developed and perfected Just-In-Time (JIT) system of manufacturing that eliminates the need for inventory and inventory management, thus saving considerable costs. To summarize, inbound logistics is a primary activity that creates an immense value for Toyota due to the localization of production and efficiency application of JIT supply chain system. Operations In 2013 Toyota automotive operations were reorganized into the following four units: The Lexus International. The business unit is assigned the role of the global head office for Lexus brand development, sales, marketing and advertising. Toyota No.1. This unit is in charge of North America, Europe, and Japan. Toyota No.2 unit caters for emerging markets of China, Asia & the Middle East, East Asia & Oceania; Africa, Latin America & the Caribbean Unit Cellar. This unit deals with unit-related technological development, manufacturing technology development and production Toyota promotes a spirit of monozukuri i.e. conscientious…